1. Garments Washing

Chapter Outline

- Definition

- Requirements of garments washing

- Types of garments washing

- Process (objectives, chemical name, chemical functions, flow process, standard recipe) of each washing type

- Washes

- Normal Wash

- Enzyme Wash

- Stone Wash

- Bleach Wash

- Sulphide Wash

- Acid Wash

- Pigment Wash

- Caustic Wash

- Silicon Wash

Washing Definition

Garment washing is a technology which is applied to change or modify the outlook, appearance, comfortability, design and cleaning of garments.

Types of Garments Washing

1. Wet process/Chemical process:

where no chemical or washing machines are used.

- Normal wash/ garment wash/rinse wash

- Pigment wash

- Caustic wash

- Enzyme wash

- Stone wash

- Stone enzyme wash

- Super white wash

- Bleach wash

- Acid wash

- Silicon wash

- Soft wash

2. Dry process/Mechanical process:

where chemical and washing machines are used.

- Sand blasting

- Whisker

- Hands brush

- Over all wrinkles

- Permanent wrinkle

- Broken and tagging

- Grinding and destroy

- PP spray and PP sponging etc.

Objectives or requirements of Garments Washing

- To remove dirt, dust and waste materials from garments.

- To remove size materials from garments.

- Give soft hand feel.

- To improve outlook or appearance of garments.

- To improve color fastness and abrasion resistance property.

- To increase the brightness of garments.

- To increase the smoothness of garments.

- To make directly wearable after purchase.

- To remove harmful materials from garments.

Wet Process

Washing Chemicals

- Enzyme: Used in enzyme washing & hydrolyses the cellulose to remove color to produce fading effect.

- Detergent: Used in normal wash to remove dirt, dust, sizes and waste materials from garments.

- Acetic Acid (): Neutralize the garments in alkaline condition.

- Anti staining agent

- Bleaching agent: Oxidizing agent.

- Sodium Hyposluphite (): Neutralize the garments in acidic condition.

- Caustic Soda (): Used in caustic wash to remove color from garments.

- Soda Ash(): Creates alkaline medium for the breakdown of pigment dye.

- Sodium bicarbonate (): Used in washing plant in the bleach bath with bleaching powder for Denim Light shade because it can easily color fade with in shot time.

- Potassium Permanganate (): Used in Acid wash with Pumice stone for color out from the garments.

- Softener: Imparts soft and silky feel.

- Micro emulsion silicon: Gives durable softness, lubricity, elastic handle, anti-pilling.

- Sodium Chloride (): It helps to exhaust dye in to the fiber.

- Buffer: Controls the pH of the bath.

- Hydrogen peroxide (): Breaks up and gives some per hydroxhyl ion, which discolor the coloring materials and as a result fading effect is developed.

- Stabilizer: used to protect break of hydrogen peroxide and it works in bath smoothly.

- Fixing agent: Used for unfixed dye to fix on fabrics.

- Optical brightener: used for improve the brightness of garments.

- Resin: Used for the creation of semi-permanent creases in denim and other cellulose fabrics.

- Sodium Meta Bi Sulphite (): Used in the washing plant to neutralized the garment from potassium permanganate.

- Desizing agent

Machines Used in Washing Section

- Washing machine: Washing machine is the machine used to wash the various types of clothes without applying any physical efforts.

- Types of washing machine:

- Front Loading Washing Machine.

- Side Loading Washing Machine.

- Vertical loading washing machine.

- Horizontal loading washing machine.

- Stone Washing Machine.

- Semi-automatic washing machine.

- Fully automatic machine.

- Types of washing machine:

- Hydro extractor

- Dryer

- Industrial Oven

- Boiler

Standard Flow Process of Apparel Washing

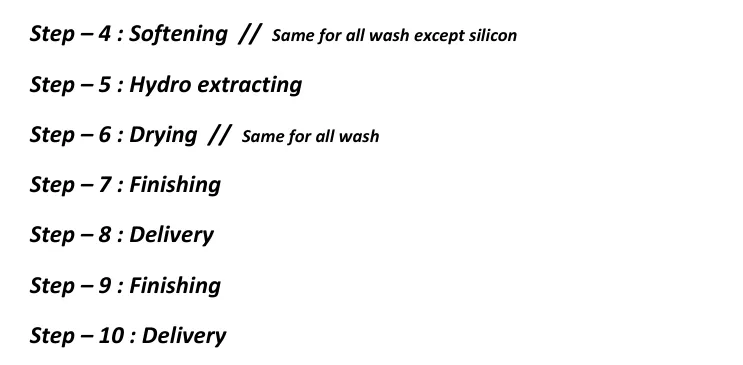

Normal Wash (Wet Process)

Flow Process

Objectives

- To remove dust, dirt, oil spot, impurities from the garments.

- To remove size materials from the garments.

- For soft feeling to wear the garments after purchasing.

- To achieve buyer washing standard.

Enzyme Wash

Enzymes are bio chemical substances that behave as catalysts toward specific reactions.

Advantages or Objectives of Enzyme Wash

- “Bio-Polishing” effect of cotton/denim.

- Enzyme attack as chemically not mechanically for this reason low damage/wastage.

- For soft feeling to wear the garment. Enzyme attacks more the surface of the fabrics and gives a very smooth surface.

- To remove the size materials from the garments.

- To remove the starch presents on the garments fabrics.

- To achieve the buyer reference sample.

- To increase the color fastness & rubbing fastness.

- Enzyme improves the anti-pilling properties.

Why Enzyme wash is preferred?

- Enzyme attacks more the surface of the fabrics and gives a very smooth surface.

- Enzyme attack as chemically not mechanically for this reason low damage/wastage.

- Operate at low temperature.

- Replace harsh chemicals.

- Eco-friendly.

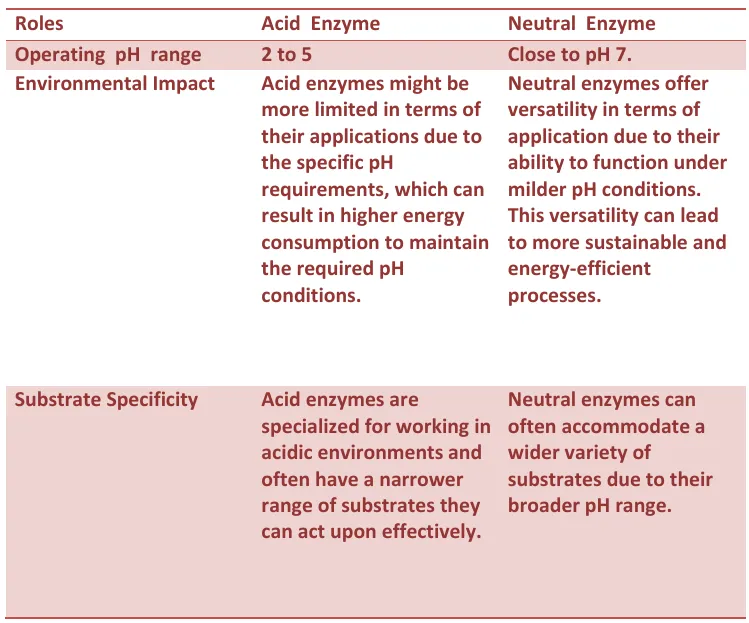

Acid Enzyme vs Neutral Enzyme

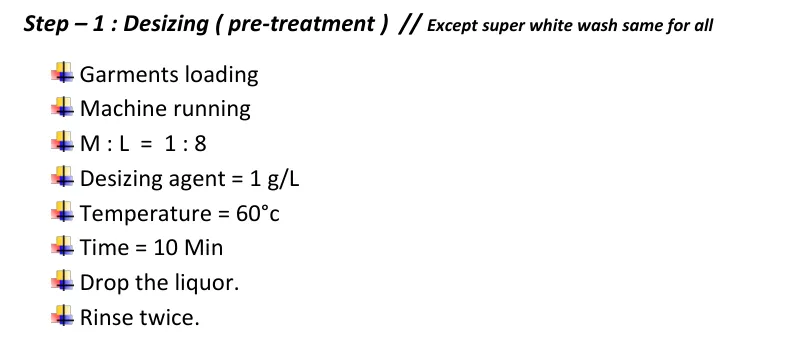

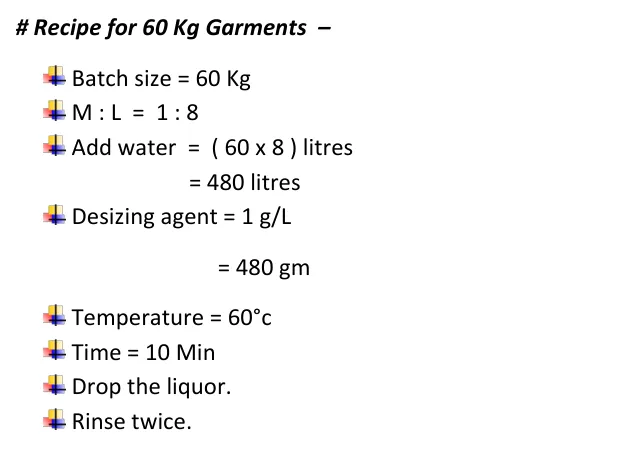

Flow Process

Recipe

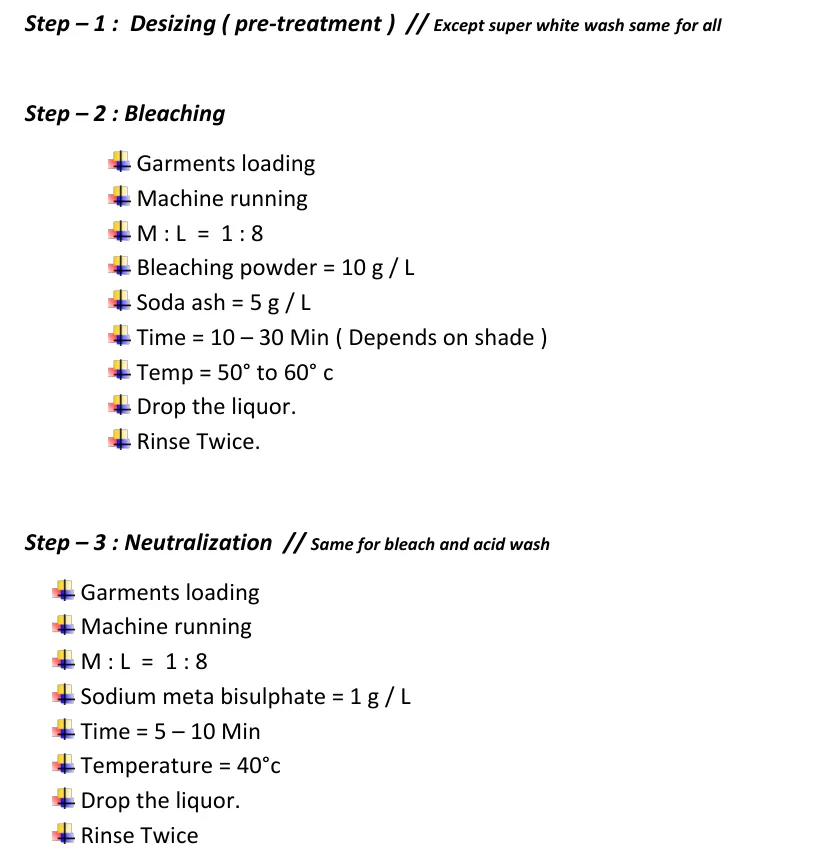

Bleach Wash

Objectives

- Destroy natural color.

- Rubbing fastness remove.

- Color fading.

Flow Process

Recipe

Enzyme vs Bleach Wash

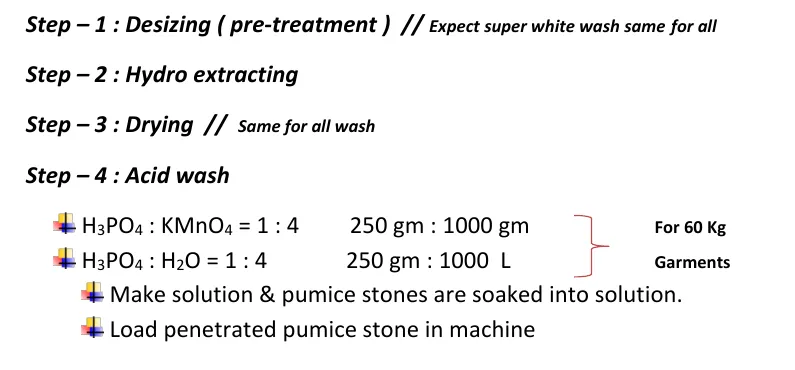

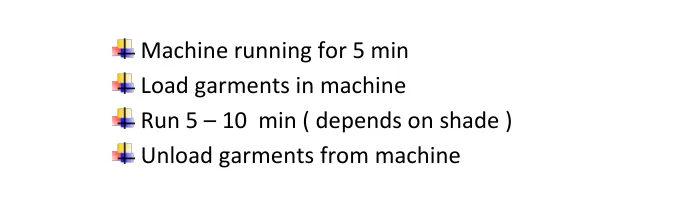

Acid Wash

Use of Pumice Stone

During Acid wash, pumice stones are used. By the action of pumice stones, irregular fading effect is developed on the heavy garments like denims, thick canvas/twill, and sweater.

The pumice stones act as a brushing action on the garment fabric surface. The area where more brushing action takes place; more discolor or fading effect is developed and the area where less brushing action takes place less fading effect will be developed.

The multi-layer fabric areas like – collar, cuff, pocket, placket, side seam etc. area will be brushed more than the single layer areas. As a result irregular fading affect will be developed on the garments’ fabric surface. In this way, fading affect may be developed on the garments by acid wash technique.

Usage of KMnO4 with pumice stone:

Pumice stones are soaked with KMnO4 ; chemical stays on stone surface which give effect.

Without stone only KMnO4 will give uniform fading effect which is not desirable ; for irregular fading stone is used. As in machine, stone comes with surface contact of fabric irregularly & irregular fading is obtained which is desirable.

Advantages of pumice stone:

- Desired vintage effect on garments can be easily achieved by using pumice stones.

- Washed garments can achieve more soft effect by using pumice stones.

Disadvantages of pumice stone:

- Can be damaged washing machine due to stone and machine abrasion.

- Garments can be damaged due to stone and machine abrasion.

Objectives:

- Irregular fading.

- Buyer requirement.

- For soft feeling to wear the garments i.e. to improve softness.

- To increase rubbing fastness.

- To remove dust, dirt, oil spot, impurities from the garments.

- To remove size materials from the garments.

Flow Process

Questions

Q1: After loading pumice stone why machine runs before loading garments?

Stone needs to soak with chemical KMnO4; then put in to machine. Before loading garments machine runs so that chemical can spread into machine uniformly. After that it is ready for operation.

Q2: Why load garments into another machine?

Previous machine is filled with KMnO 4 which is an oxidizing agent. It produces fading in fabric. Next step is neutralization ; if same machine is used we need to remove KMnO4 first. It will be a time consuming process. So use of another machine will be time efficient.

Recipe

Note: Bleach wash & acid wash’s neutralization is same except sodium hyposulphite is used in acid wash instead of sodium meta bi sulphate.

Factors of Fading

- RPM of machine.

- More RPM = More fabric surface will be fade.

- Less RPM = Less fabric surface will be fade.

- Squeeze & pressure (knit)

- Less squeeze bandage ; less chemical ; less effect

- Time

- Concentration

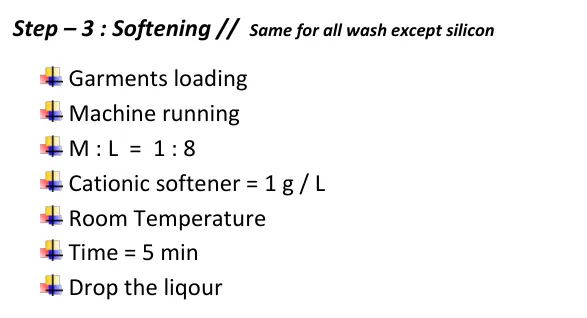

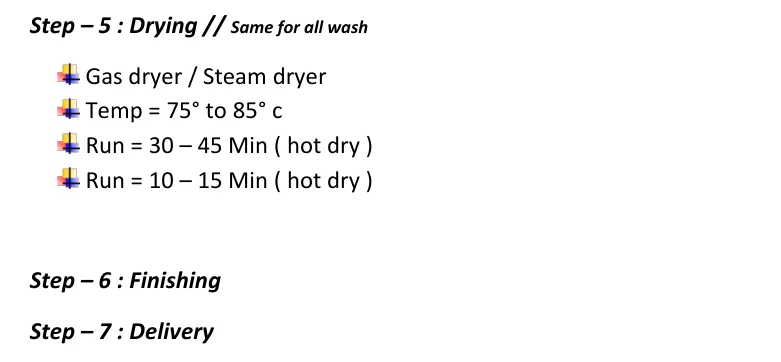

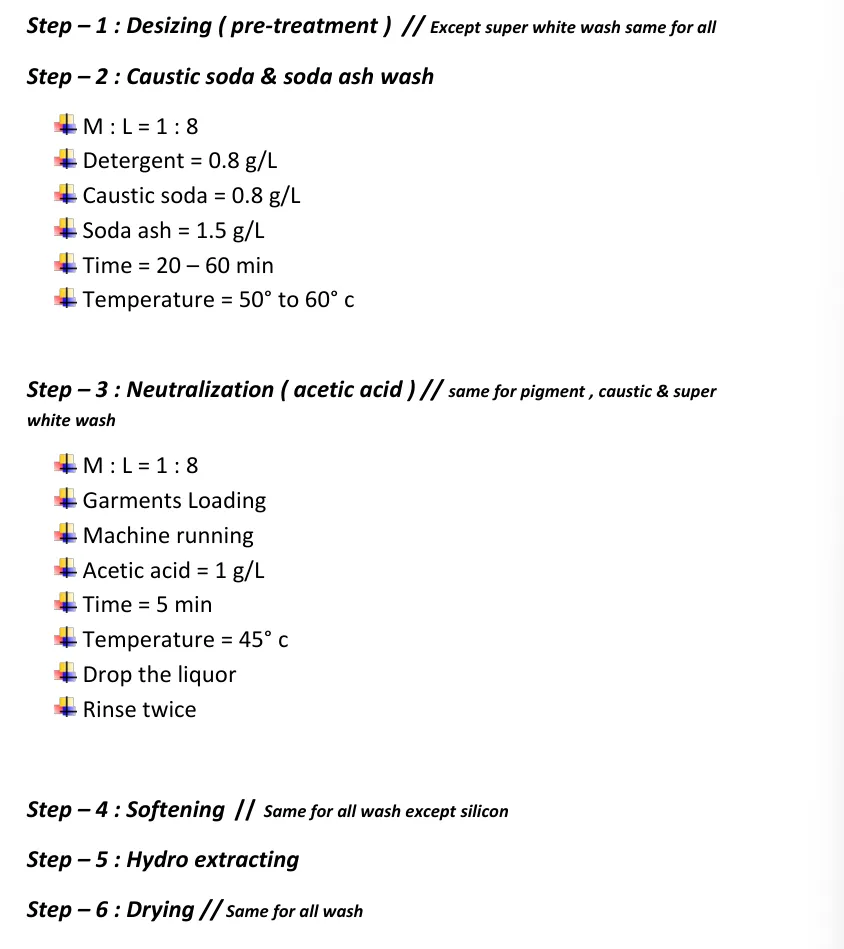

Flow process of pigment, caustic & silicon wash

![]()

Pigment Wash

Its similar to normal washing process and applicable for pigment dyed fabric.

Objectives

- To wash pigment dyed fabric.

- To give color fading effect.

- To remove dust, dirt, oil spot, impurities from the garments.

- To remove size materials from the garments.

- For soft feeling to wear the garment after purchasing.

- To increase the color and rubbing fastness.

- To achieve buyer washing standard.

Recipe

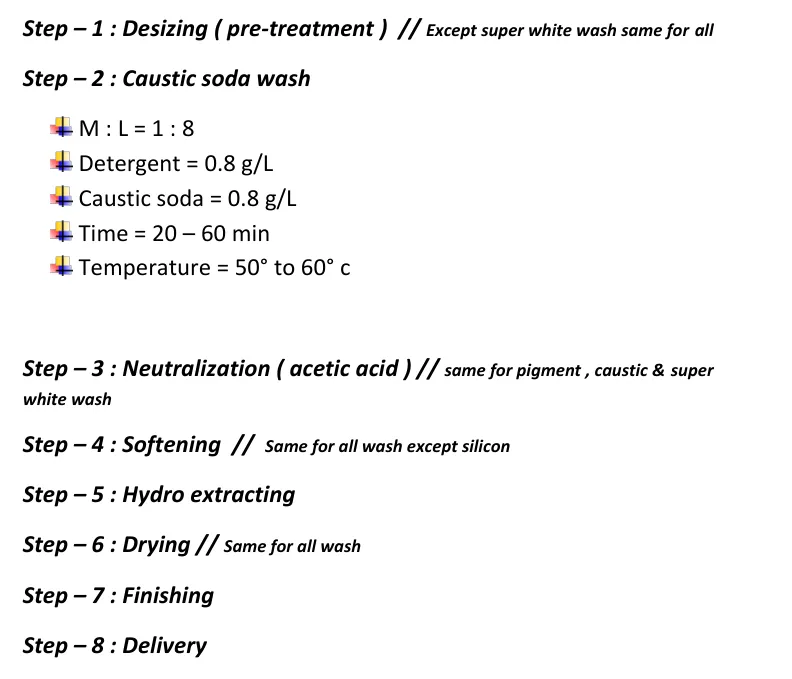

Caustic Wash

Normally printing on fabric is done after pre-treatment that is desizing, scouring & bleaching.

But for caustic wash, printing is done without pre-treatment.

Objectives

- To fading/old looking effect on Garment and seam abrasion affection seam area.

- To remove the size materials, starch from the garments.

- Dust, dirt, oil spot, impurities etc. are removed that may come from during process i.e. cutting, stitching and the back process.

- To increase the color fastness & rubbing fastness.

- For soft feeling to wear the garments.

- To increase the hairiness on garments this increases its old look appearance.

- To achieve the buyer reference sample.

Recipe

Silicon Wash

Silicon washes are generally done on all type of fabrics.

Objectives

- It gives durable softness, elastic handle,

- It helps to anti pilling affects, dimensional stability, tear resistance.

- It helps to fabrics to be cut and sewn more easily allows.

- Improve wears and easy care properties.

Recipe

![]()

Super White Wash

To be added.

Washing Parameter/Condition

Washing Faults

- Bleach spot

- Over grinding

- Shade variation

- Crease mark

- After wash hole

- Poor brightness

- Poor handfeel

- High low effect

- High hairness

- Over blasting

- Spot on garments

- Bad smell due to poor neutralization

Prevent of back staining

- Use limited softener

- Use anti-staining agent

- Use better dye

Contributions

- Shakib Hasan Shuvo